CUSTOM

shock absorbers

& landing gear

We design, develop and qualify shock absorbers

tailored to your specific needs.

Since 2005, Soben has been developing high-performance, fast and uncompromising suspension solutions.

We support our customers with responsiveness, rigor and high standards, offering shock absorbers renowned for their reliability and efficiency. At Soben, we refuse to compromise: each solution aims for technical and economic excellence, without ever compromising on quality.

Our expertise is recognized in the most demanding applications.

Our shock absorbers are fitted as original equipment on vehicles and machines from all horizons : sports cars, off-road vehicles, mobile robots, autonomous vehicles, tanks, flying taxis, passenger aircraft, helicopters, drones, space launchers, cable-stayed bridges, cable cars, skis, agricultural machinery, and many more.

OUR EXPERTISE

Soben has mastered the art of damping.

Whatever the damping law to be reproduced, we know how to design a tailor-made solution to generate the desired force.

We develop systems capable of responding to laws that depend on.

Position

Speed

Acceleration

Frequency

Temperature

More than just shock absorbers, we have complete expertise in dynamic behavior.

Soben can help you define your suspension system and optimize suspension kinematics to improve your vehicle’s handling, comfort and safety.

Our expertise also extends to drawing up validation and qualification plans. Thanks to our in-house test benches and a proven network of specialist partners, we can cover all standard and specific tests, even the most complex.

Soben is your expert partner, involved at every stage of the project, from expression of need through development, vehicle testing, validation and industrialization to series production.

Intelligent hydraulic stops for progressive and effective damping.

Soben has developed hydraulic stops capable of generating a controlled increase in force at the end of the compression stroke. This force, which is proportional to both speed and position, adapts automatically to the intensity of the load.

To limit excessive compression stress, a force limiter has been integrated directly into the hydraulic bump stop. This technology maintains a low level of damping around the static position – improving comfort and traction – while providing progressive hydraulic damping at the end of the stroke, ideal for gently slowing wheel movement.

Energy dissipation at the end of the stroke eliminates any undesirable rebound phenomenon, guaranteeing greater dynamic stability.

Thanks to our perfect mastery of this technology, we can develop all types of customized damping laws : PROGRESSIVE, LINEAR, EXPONENTIAL.

Our hydraulic bump stops are particularly economical, efficient and reliable. They can be fitted to all twin-tube dampers.

Double-acting hydraulic stop : integrated, efficient and durable technology.

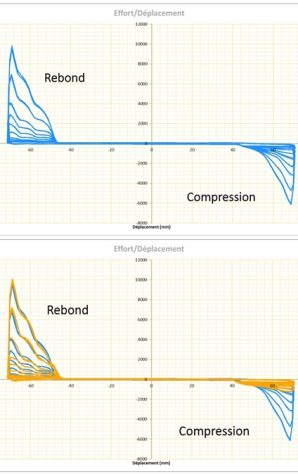

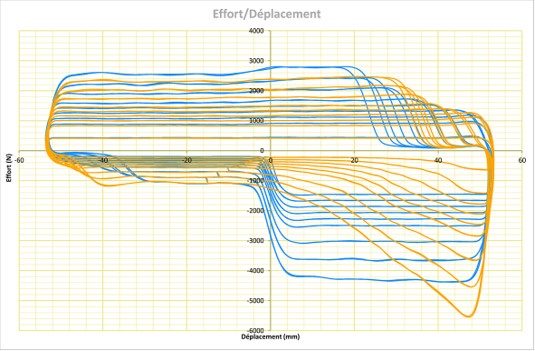

Soben has developed an innovative hydraulic stop that acts both in compression and rebound. This compact system is particularly well suited to high-pressure monotube dampers, with a single device providing both hydraulic stop functions.

The graphs opposite are taken from measurements made on our in-house characterization benches. They illustrate clean, stable and perfectly reproducible damping laws. Our extensive endurance tests have confirmed the excellent long-term performance of this solution.

The compression force limitation system can be set to a very low threshold, without interfering with the operation of the rebound stop. Thanks to this technology, we can design tailor-made damping systems that optimize the dynamic performance, ride comfort and safety of your vehicles.